Table of Contents

1. The Brave New World of PCB Design Validation – Cloud-based DFM and Collaboration

- Trend of customization of electronics

- Shorter development cycles in electronics industry

- Is supply chain really an issue in the electronics industry

- SMBs in the electronics industry, with focus on EMS

- Market Trends for adoption of cloud based tools

- MFTPaaS – managed file transfer platform as a service

- Migration to the cloud

- Cloud based solutions for PCB manufacture

- The Next Logical Step: Moving Design for Manufacture (DFM) Analysis into the Cloud

Today’s electronics industry is grappling with increasing demand for more customized products, shorter development cycles, supply chain disruptions, and tighter margins. In the PCB manufacturing market, SMBs now outnumber enterprise OEMs by 4 to 1; lifecycle processes are often siloed and handled by geographically disparate teams. Having already established that Design for Manufacture and Supply Chain confirmation are vital and valuable components in the product lifecycle, we propose that the next logical step is bringing collaborative analysis capabilities to the cloud to create a digital twin of the PCB lifecycle and align all stakeholders with a common goal.

This paper reviews market trends for adoption of cloud-based tools, correlated from independent research and publicly available sources. Real world case studies are used to examine how cloud-based DFM and collaboration is changing the playing field by enabling egalitarian access to information that affects planning, influences decisions and reduces time-to-market.

Trend of customization of electronics

As electronic devices become more and more commonplace in our everyday lives, there is an increasing demand for devices that are customizable to our individual needs. This trend is being driven by the rising popularity of the Internet of Things (IoT), as well as the ever-expanding capabilities of modern electronics.

One of the key benefits of customization is that it allows electronic devices to be better tailored to our specific needs and preferences. For example, if you are a light sleeper, you can now buy a smart alarm clock that can be programmed to wake you up at the lightest point in your sleep cycle. Or if you are a fitness enthusiast, you can purchase a wearable device that tracks your activity level, heart rate, and sleep quality.

Customization also allows for greater personalization of our electronic devices. We can now choose the color, style, and even the functionality of our devices to match our personal taste. And as more and more devices are connected to the internet, we can also customize their settings and applications to our liking.

The trend towards customization is being driven by a number of factors. Firstly, the IoT is making it possible for devices to be connected and controlled via the internet, which opens up a whole world of possibilities for customization. Secondly, the ever-increasing capabilities of electronic devices are making it possible to create ever-more sophisticated and personalized devices. And finally, as our lives become ever more reliant on electronic devices, we are increasingly demanding that they meet our specific needs and preferences. So, it is clear that the trend towards customization is here to stay. As electronic devices become more and more integral to our lives, we will continue to demand devices that are tailored to our individual needs and preferences.

References: nytimes.com >>

Forbes.com >>

Shorter development cycles in electronics industry

The trend of shorter development cycles for electronic products is driven by the need for faster turnaround times and the desire to get products to market quickly. This has led to an increase in the use of agile development methodologies, which emphasize shorter development cycles and continuous delivery.

There are a number of benefits to shorter development cycles, including the ability to respond quickly to changes in the market and customer demands. shorter development cycles also allow for more frequent release of new features and functionality, which can help to keep customers engaged.

However, shorter development cycles can also lead to increased pressure on development teams, and can make it more difficult to ensure the quality of the final product. There is also the risk that products may be released before they are fully ready, which can lead to customer dissatisfaction.

Despite the challenges, the trend of shorter development cycles is likely to continue, as the benefits outweigh the risks. Development teams that can adapt to the challenges and learn to work in an agile way will be well-positioned to succeed in the future.

Digitization of factories to improve efficiency and shorten NPI process (statistics) >>

https://www.pwc.de/de/digitale-transformation/digital-factories-2020-shaping-the-future-of-manufacturing.pdf

Is supply chain really an issue in the electronics industry?

In today’s business world, the supply chain is critical to the success of any company, but especially so in the electronics industry. This is because the electronics industry is extremely globalized, with components and finished products being sourced from all over the world.

A company’s supply chain is the network of suppliers, manufacturers, warehouses, and distribution centers that are involved in getting a product from the raw material stage to the finished product stage. In the electronics industry, the supply chain is often very complex, with components coming from different countries and being assembled in another country.

A disruption in any part of the supply chain can have a major impact on a company’s bottom line. For example, if a component supplier goes out of business, it can delay the production of finished products and lead to lost sales. That’s why it’s so important for companies in the electronics industry to have a well-run supply chain. A good supply chain management team will work to minimize disruptions and keep costs low.

An efficient supply chain is also important for another reason: time to market. In the electronics industry, new products are constantly being introduced and the competition is fierce. Companies that can get their products to market quickly have a major advantage.

https://www.cio.com/article/400404/supply-chain-issues-a-top-concern-across-most-industry-sectors.html

A report from electronic components and semiconductor distributor, Avnet Silica.

The report, which is based on a study conducted by Avnet consultants after reviewing 30,111 earnings call across different sectors between January 2018 and April 2022, points out that supply chain issues occupied more than 60% of airtime in earnings calls across all industries in 2022, compared to just 47% and 37% in 2021 and 2020 respectively.

A separate report from market research firm International Data Corporation (IDC) expects tight semiconductor supply to continue through the first half of 2022 as the industry builds up inventory to normal levels.

The 20 industries included in the Avnet Silica report include consumer electronics, automotive, aerospace and defence, telecom, fashion, retail, conglomerate, beverages and farming.

The report also says that as semiconductor shortages continued to grow, supply chain issues were brought up on 100% of earnings calls in 12 different sectors this year, including automotive, electronic components, computer hardware and consumer tech. Other factors heavily plaguing enterprises across these sectors include inflation and issues around talent.

A side effect of raw material shortage is the increase in prices along the supply chain — from manufacturing and shipping to assembly and final cost at the retail store. On top, of course, of limited inventory available. Chip component prices rose 40%, following a significant shortage in January 2021 when demand skyrocketed. One of the leading chip manufacturers, Taiwan, suffered substantial setbacks due to the pandemic.

Example in the automobile electronics industry:

https://www.eetimes.com/second-wave-of-supply-chain-woes-looms/

“But there’s even more at stake because the product has fundamentally changed, said Swiecki, as consumers increasingly become more accepting of electric vehicles. “The technology has matured. The little foundational elements that we need are now in place, and we’re seeing it all really have impact.” With that segment of the market growing, it’s place pressure on the semiconductor supply—not just for the vehicles themselves, but infrastructure to support these vehicles such charging stations. And the more purely electric the vehicles, the more processors are required in the power train. “They demand more semiconductors for us to build one of these vehicles.”

Compounding the semiconductor supply challenge new methodologies including a push by the federal government incentives we incentivize these vehicles, said Swiecki. “It won’t happen unless we’ve got the chips.”

By 2028, forecasts predict 7 million units of electric vehicles in production in the United States, which means massive demand for chips. “In terms of the automotive development cycle, which is years, 2028 might as well be tomorrow,” Swiecki said. And that’s just the electric vehicle market, he said. There’s also the automated vehicle content. “We are transforming this industry to start making vehicles that drive themselves.” “

Supply Chain intellectual security is a hidden issue that makes procurement even more challenging

With the proliferation of the Internet of Things (IoT), the risks associated with supply chain security have increased exponentially. The electronics industry is built on a global supply chain that is often complex and opaque. Components and finished goods are sourced from all over the world, and the lines between original equipment manufacturers (OEMs), contract manufacturers (CMs), and original design manufacturers (ODMs) are often blurred.

This complexity makes it difficult for companies to know where their products are at all times and makes it easier for criminals to introduce counterfeit parts or steal IP. In addition, the electronics industry is under constant pressure to innovate and bring new products to market quickly. This pressure can lead to shortcuts in the supply chain that can create vulnerabilities.

According to the US Department of Homeland Security, the global trade in counterfeit electronics is estimated to be worth $100 billion annually. The theft of IP and trade secrets is even harder to quantify, but the cost to companies can be significant.

In 2011, the US National Security Agency (NSA) estimated that the cost of intellectual property theft to the US economy was $250 billion per year. A recent study by the Commission on the Theft of American Intellectual Property estimated that the annual cost to the US economy was actually $600 billion.

The risks associated with supply chain security are not just financial. They also include reputational damage, loss of competitive advantage, and even national security risks.

In 2012, the US Department of Defense (DOD) was the victim of a major supply chain security breach.

A Chinese company was able to insert malicious code into networking equipment that was being shipped to the DOD. This code allowed the Chinese to remotely access the equipment and collect sensitive information. The incident highlights the fact that supply chain security breaches can have serious national security implications.

The electronics industry is taking steps to improve supply chain security. The US government has also been working to raise awareness of the issue and has taken action to protect the US supply chain. In 2013, the US Congress passed the National Defense Authorization Act, which included provisions to improve supply chain security. The act requires the DOD to develop a plan to assess the risks associated with the global supply chain and to take steps to mitigate those risks. The US government has also been working with the private sector to improve supply chain security.

In 2014, the Obama administration launched the National Strategy for Global Supply Chain Security. The strategy includes a number of initiatives to protect the US supply chain, including enhancing information sharing, developing new standards, and increasing international cooperation. The criticality of supply chain security has been highlighted in recent years by a number of high-profile incidents. The risks are real and the stakes are high. The electronics industry is taking steps to improve supply chain security, but more needs to be done.

SMBs in the electronics industry, with focus on EMS

Infographic: https://www.technavio.com/report/electronics-manufacturing-services-market-industry-analysis >>

According to a Technavio report from 2021, The electronics manufacturing services (EMS) market size has the potential to grow by USD 121.80 billion during 2021-2025, and the market’s growth momentum will accelerate at a CAGR of 4.95%.

The global electronics industry is forecast to grow at a compound annual rate of 4.4 percent between 2019 and 2022, according to market research firm Technavio. This growth will be driven by the continued expansion of small and medium-sized businesses (SMBs) in the sector, the report said. SMBs are expected to account for a larger share of the electronics industry’s revenue growth during the forecast period, as they are increasingly adopting new technologies and expanding their product portfolios.

The electronic design automation (EDA) for PCB and MCM market has the potential to grow by USD 216.97 million during 2021-2025, and the market’s growth momentum will accelerate at a CAGR of 5.38%. The demand for electronics manufacturing services is estimate to grow due to rising healthcare, automotive and industrial applications. Additionally, the service providers heavily focus on providing functionalities such as sub-assembly manufacturing, testing, designing printed circuit boards (PCBs), and component assembly & re-engineering. It is subsequently driving the market growth over the forecast period.

The global electronic manufacturing services market is projected to grow from USD 504.22 billion in 2022 to USD 797.94 billion by 2029

India as an example:

https://www.business-standard.com/article/sme/domestic-electronics-sector-set-to-grow-12-17-in-fy22-crisil-sme-tracker-121052701386_1.html

The domestic electronics sector’s revenue is set to rebound 12-17 per cent to ~8-8.3 trillion in the current fiscal year (FY22), helped by the low-base effect of fiscal year 2021 and government facilitations such as the Production-Linked Incentive (PLI) scheme, which promotes manufacturing rather than just assembling of products. …The outlook, therefore, has improved for the domestic electronics sector, including small and medium enterprises (SMEs) that account for 20-40 per cent of the industry’s revenue.

The electronics industry is highly competitive, and SMBs are under pressure to continuously innovate and offer unique products and services to survive and thrive. They are investing in research and development (R&D) to develop innovative products and services.

SMBs are also investing in new technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and 5G, to gain a competitive edge. The adoption of these technologies will help SMBs improve their operational efficiency, reduce costs, and offer better customer experiences. The growing adoption of cloud computing is another trend that is expected to drive the growth of the electronics industry during the forecast period. Cloud computing enables SMBs to store, process, and access data and applications over the internet. It helps them save on infrastructure costs and makes it easier for them to scale their businesses.

SMBs are vital to the electronics industry. They provide many of the products and services that larger businesses and consumers depend on. For example, SMBs make the printed circuit boards that are found in almost all electronic devices. They also design and manufacture the electronic components that go into these devices. In addition, SMBs provide assembly, packaging, and other services to the electronics industry.

In spite of their importance, SMBs face many challenges. They often lack the financial resources and the economies of scale that larger businesses have. As a result, they may find it difficult to compete against larger businesses. In addition, SMBs may have difficulty accessing the latest technology and tools. They may also struggle to attract and retain qualified employees. Despite these challenges, SMBs play a vital role in the electronics industry. They provide many of the products and services that businesses and consumers rely on. With the right support, they can continue to thrive and contribute to the industry’s success.

- When looking for new technology, the top factors SMBs look for are ease of use (69%), trustworthy vendor (63%), and price (61%). (Salesforce, 2019)

- About 85% of small companies have already invested in Software as a Service (SaaS) products and solutions. (BMC, 2020)

- On average, small companies with 50 employees or less use 25 to 50 SaaS solutions. (BMC, 2020)

Market Trends for adoption of cloud based tools

The market for cloud-based tools is growing rapidly, with more and more businesses of all sizes adopting these tools to improve their efficiency and productivity. Some of the latest trends in the adoption of cloud-based tools include:

- Businesses are increasingly adopting cloud-based tools to improve their agility and flexibility.

- Cloud-based tools are becoming more and more user-friendly, making them easier for businesses to adopt.

- The cost of cloud-based tools is dropping, making them more affordable for businesses.

- The security and reliability of cloud-based tools is improving, making them more attractive to businesses.

- More and more businesses are realizing the benefits of cloud-based tools and are making the switch from traditional on-premise tools.

These trends indicate that the market for cloud-based tools will continue to grow at a rapid pace in the coming years. Businesses that have not yet adopted these tools should do so as soon as possible to stay ahead of the competition.

MFTPaaS (managed file transfer platform as a service )

Research Nester has published a detailed market report on ‘Global MFTPaaS Market’ for the forecast period, i.e., 2022 – 2031 which includes the ongoing industry innovations and recent trends being adopted by the major industry players to achieve their business targets. The global MFTPaaS market is estimated to grow at a CAGR of ~16% during the forecast period.

MFTPaaS or managed file transfer platform-as-a-service offers a secure and managed end-to-end data transfer gateway. The market is estimated to expand as a result of both the increasing need for secure data transfer over the internet and the expanding usage of cloud computing technology. The World Data Bank reports that between 2014 and 2020, the global exports of ICT products climbed from 11.4 percent to 14.3 percent of total exports of goods. Hence, the rising technological advancement and growing ICT sectors are estimated to propel the global MFTPaaS market growth outlook over the forecast period.

The printed circuit board (PCB) industry is under pressure to improve productivity and efficiency in the face of intensifying global competition. In response, many PCB manufacturers are turning to cloud-based solutions to help them streamline their operations.

Migration to the cloud

82% agree the cloud migration provider they selected was a key partner in their migration success.

“Which of the following are the most important business outcomes your organization expects/has experienced as a result of migrating to cloud?”

- 53% Better end-user experiences from apps running in cloud*

- 52% Better positioned to focus on innovation (versus day-to-day infrastructure management)

- 50% More reliable platform for workloads

References: https://services.google.com/fh/files/misc/googlecloudmigrationsnapshotreportfinal2022.pdf >>

https://devops.com/a-guide-to-cloud-migration-trends-and-strategies/amp/ >>

In 2021 alone, companies spent $410.9 billion on public cloud services, and Gartner expects this number to rise by 20.4% in 2022 to reach $494.7 billion.

Nearly two-thirds of SMB workloads will be in cloud SMBs are moving quickly to the public cloud. As Figure 17 indicates, 69 percent of SMB workloads and 67 percent of data will reside in a public cloud within the next 12 months. Organizations are open to moving sensitive data to the cloud In the past, some organizations hesitated to put certain types of data in public clouds. This year’s survey found many respondents are reconsidering. As Figure 19 shows, more than half of respondents said they’ll consider moving at least some of their sensitive consumer data or corporate financial data to the cloud, which reflects increasing confidence in the security practices of cloud providers.

Cloud based solutions for PCB manufacture

Cloud-based solutions offer a number of advantages for PCB manufacturers. Perhaps most importantly, they can help to improve communication and collaboration between different departments within a company. By bringing all of a company’s data and applications into the cloud, everyone can access the information they need from any location. This can help to improve decision-making and reduce the risk of errors.

In addition, cloud-based solutions can help PCB manufacturers to save money. By reducing the need for on-site hardware and IT staff, companies can reduce their overhead costs. And because cloud-based applications are typically subscription-based, companies only pay for what they use, making them more scalable and cost-effective.

Finally, cloud-based solutions can help PCB manufacturers to be more agile and responsive to change. With the ability to quickly deploy new applications and services, companies can experiment with new processes and procedures without the need for costly and time-consuming IT projects.

The benefits of cloud-based solutions are clear. For PCB manufacturers looking to improve their operations, the cloud is an increasingly attractive option

Reference: https://www.wevolver.com/article/cloud-manufacturing-services-deliver-new-pcb-possibilities >>

“Over the last couple of years, Electronic Manufacturing Services 2.0 (EMS 2.0) has emerged as a service-oriented approach to product development that creates a shared resource pool and a network of suppliers that individuals or organizations can utilize to turn their ideas into reality. The service provides capabilities and resources through an online platform, from where customers can pick the most viable manufacturing specifications for their products. Cloud manufacturing services can be used to set up a virtual enterprise or a dynamic chain of service providers for customers to avail customized services.”

“The ultimate aim of cloud manufacturing, just like any other tech framework, is to make the lives of engineers easier so that they can shift their focus from the process to innovation. Some key benefits of cloud manufacturing services are:

- Fast quotes: It is possible to view BOM and quotes from different service providers right after uploading the PCB design. This establishes a minimum base rate for the job, and while unforeseen circumstances may occur, customers can plan for the other project-related expenses in a much better way.

- Easy component procurement: Cloud manufacturing service providers share a BOM and quote upfront before acquiring components and getting PCB manufactured. This way, users can get an estimate of expenses that would be incurred.

- Customized recommendations: Cloud manufacturing service providers deploy Artificial Intelligence (AI) based recommendation systems that help customers pick the right service providers based on quality, capability, volume, pricing, and more.

- Real-time support: A dedicated support team is available with cloud manufacturing service providers to ensure the resolution of queries in real-time.

- Simplified project management: Cloud manufacturing service provides a “360° view” of everything going on in the organization. It simplifies project management by providing deep insights into the progress. This helps in better management of resources and planning for the action items.

- Supply chain resilience: Standardization of the process enables factory portability which is currently as hard as it can get, and almost non-existent in the electronics manufacturing industry. Read more on this in our article on Supply Chain Resilience For PCBs.

- Access to low-cost manufacturing: Due to the lack of logistic facilities, sometimes it gets difficult for users to get in touch with low-cost manufacturing service providers. Having a cloud manufacturing service opens up the possibilities to explore multiple suppliers to understand who offers the best pricing.

- Scalability: Contract manufacturers working on a small-scale lack the ability to handle bulk orders, and those working on a large-scale lack the flexibility and affordability to work on a small order. It becomes necessary to switch from one manufacturer to another as the project passes through the various levels of its lifecycle. With cloud manufacturing services, it becomes possible to scale from one to a million at a single place.

- Uncertainty management: The solutions, resources, and services required for managing a job can be commissioned or decommissioned based on the demand. This enables users to be dynamic with the order size.

- Increases profitability: The ultimate goal of making improvisations in the existing system of manufacturing is to make more profits. Given the advantages that cloud manufacturing services offer, organizations are more likely to make higher profits by implementing the cloud-driven approach.”

As the world increasingly moves toward cloud-based services, more and more companies are finding that their electronic design needs can be met using cloud-based tools and platforms. While there are still some companies who cling to on-premises electronic design tools, the trend is definitely moving toward the cloud. Here are a few examples of companies who are making the switch to cloud-based electronic design:

- Autodesk: One of the world’s leading providers of 3D design software, Autodesk has been moving more and more of its offerings to the cloud in recent years. In 2015, the company announced that its flagship product, AutoCAD, would be available as a cloud-based service. Since then, Autodesk has continued to add more and more cloud-based design tools to its portfolio.

- Siemens: Another leader in the world of electronic design, Siemens has also been moving to the cloud in recent years. The company’s flagship product, NX, is now available as a cloud-based service. Siemens has also been investing in cloud-based design tools for its other products, including its Teamcenter software. 3

- PTC: A major player in the world of product lifecycle management (PLM) software, PTC has also been moving to the cloud with its electronic design offerings. The company’s Windchill PLM software is now available as a cloud-based service, and PTC has been investing in other cloud-based design tools as well.

- Dassault Systèmes: A leader in 3D design and PLM software, Dassault Systèmes has also been moving to the cloud with its electronic design offerings. The company’s Solidworks software is now available as a cloud-based service, and Dassault Systèmes has been investing in other cloud-based design tools as well.

- Cadence: A major player in the world of electronic design automation (EDA) software, Cadence has also been moving to the cloud in recent years. The company’s Allegro and OrCAD software products are now available as cloud-based services, and Cadence has been investing in other cloud-based design tools as well.

In May 2022, chipmaker Advanced Micro Devices Inc. announced plans to shift some of its electronic design automation workloads for chip design onto Google Cloud, in order to extend the capabilities of its own data centers and benefit from advanced networking, storage and artificial intelligence capabilities.

The Next Logical Step: Moving Design for Manufacture (DFM) Analysis into the Cloud

Following the general trends of cloudification we have examined in this paper, we propose that Design For Manufacturing (DFM) analysis is the next logical step in taking PCB design and manufacture to the cloud. There are many reasons to do this, but the most compelling are speed, collaboration, scalability and accessibility.

Speed is perhaps the most obvious reason to move DFM to the cloud. With on-premise solutions, engineers must wait to requisition, install and configure the necessary software, which is often a time-consuming step. With a cloud solution, they can get started immediately. But speed is not just about getting started quickly. Cloud-based DFM solutions can also help designers iterate faster. When you can make changes and see the results in real-time, you can experiment more and get to the optimal solution faster.

Collaboration is another key reason to move DFM to the cloud. With on-premise solutions, it can be difficult to get everyone on the same page. With a cloud solution, multiple engineers can work on the same DFM analysis at the same time. This can be a huge time-saver, especially for large projects.

Collaboration between geographically disparate design teams is no longer an issue, since all are working on the same project simultaneously. Likewise, collaboration between designer and manufacturer no longer needs to be an arduous process. Cloud storage and collaboration can offer secure data transfer between stakeholders as well as direct communication to clarify design intent and reduce time-to-market.

Design for Manufacture analysis is particularly influenced by the improved collaboration offered by the cloud environment. To date, communication between designer and manufacturer was a time-consuming process, with no standard format to accurately and efficiently convey true manufacturing constraints to designers. Manufacturing rules (DRC, DFM) had to be conveyed between parties by phone, or in complex standards documents and spreadsheets. Now, a single cloud collaboration platform can serve both designer and manufacturer, providing the opportunity for manufacturers to directly communicate both their capabilities and limitations.

Designs can be quickly modified to conform and any uncertainties can be clarified using in-app tools such as chat, notifications etc.

Scalability and resulting cost savings is the third reason to move DFM to the cloud. On-premise solutions can be limited by number of software licenses purchased, whereas cloud-based solutions are typically subscription-based with no upfront cost. Cloud-based solutions can be scaled up or down as needed, paying for what you use, resulting in cost savings. This is especially relevant tor SMBs where the use of DFM software may be sporadic and purchase of permanent tools may not be justifiable.

Accessibility: Cloud-based solutions can be accessed from anywhere, so engineers can continue to work on DFM analysis even when they are not physically in an office or on-site at the fabrication or assembly house. In the emerging post-COVID19 hybrid mode of work, this is a big advantage to maintain efficiency. The online software needs no maintenance or updating, guaranteeing access to the most recent version, latest features and functionality with no additional operator or IT investment.

These solutions are accessible to all potential users, regardless of size or budget. We expect that this egalitarian access will disrupt the balance of enterprise vs SMB in the PCB design industry since quality DFM and collaboration with previously unreachable partners is now possible.

2. A PCB DFM Checklist Helps You Pass a Design Review

Each company have an internal process to release a new PCB layout design and depending by many factors, this can be simple or very time consuming. In most of the cases there is an Excel checklist with many rows that will be validated during one or more meetings.

This checklist will start with several elements that should be present in the layout: company logo, PCB internal part-number, fiducials etc. The first group of checks are related with project identification, continuing with single PCB design, elements regarding fabrication, assembly, and testability. Before to release a new PCB layout we want to be sure that the layout is following the schematic design and we can manufacture the PCBA. The release process means to set up a meeting between the hardware engineer, layout engineer, test engineer and the process expert and to check if each point from the list is completed. A simple question from the checklist could lead in a long investigation and the meeting is over before to have a conclusion.

By using an DFM tool we can reduce the number of points from the checklist and let the layout engineer to correct the PCB design before the release meeting. Instead to measure dimension during the meeting, we can just answer the question: “Was the DFM done?” Nobody should lose time counting the number of test points or measuring the minimum distance between components. There are project specific questions that cannot be answered just analyzing the CAD, but we will have more time to focus on those.

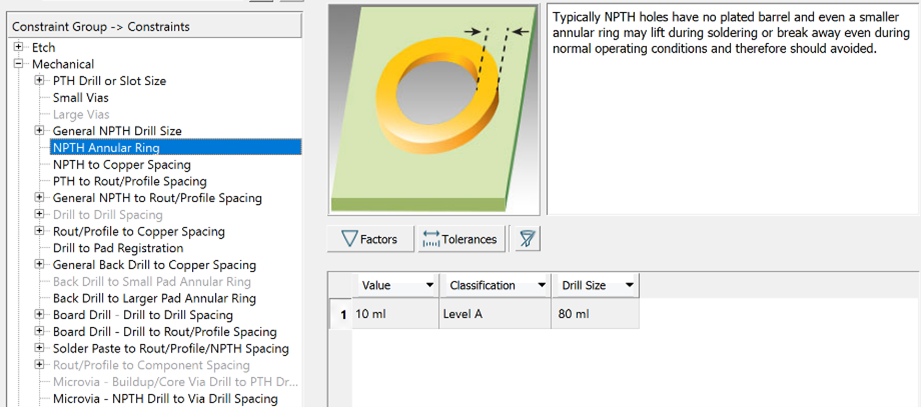

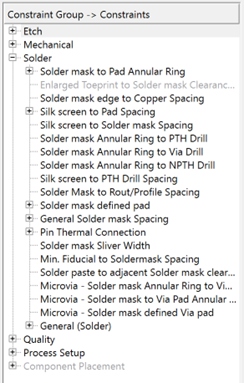

PCBFlow allows you to run the DFM check based on the PCB Fabricator Constrains Profile and see the mistakes before the layout is release. The PCBFlow Profile is like a checklist made by the PCB Fabricator available for you to check it in seconds. It is not necessary to measure the solder mask sliver width because this will be highlighted inside the DFM report. Sometimes the internal checklist is an old document that is not reflecting the latest PCB Fabricator technical capabilities. PCB Fabricators are working to improve the capabilities and if something was changed, they will upgrade the profile in PCBFlow that is immediately available.

If the second part of the checklist contains assembly contains, those can be covered by the Assembly Analyze in PCBFlow. In this case, the Profile is maintained by the Assembly Company.

The entire checklist can be converted into PCBFlow Profile and the values are updated and maintained by the PCB Fabricator and Assembly Company.

3. Introduction of Solder Mask and Its Design Tips

Years ago, I was asked to make a short between two pads in order to test a prototype. Since the resistor with the 0603 package was missing, the hardware engineer decided to continue the assembly without the component and wanted to make the short between the pads instead. Because the volume was high and the PCBs had already been ordered, I decided to change the stencil design and run the test during SMT assembly.

The result—I discovered that it was impossible to make a short if the component wasn’t placed and if there was a solder mask between the pads. The solder mask has multiple roles and, in this case, it was working against me.

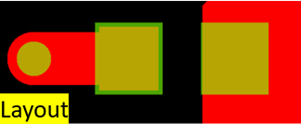

The green, blue or red material is a mandatory element covering each PCB with a protection and isolation layer. The name “solder mask” indicates its main role—to create open areas where solder paste can be added. Each component in the layout design software should contain the body geometry, lead dimension, preferred pad dimension, and solder mask shape. Industry standards recommend a minimum distance between the pad and the solder mask, but in the case of ground-floated pads, the distance is zero. We can see in the illustration that for the same component, one pad copper surface is larger than another one. It is not an issue for the functionality of the product, but it can cause trouble in production.

Let’s go back to the 0603 component and imagine that the layout engineer decided to float the pad in the GND surface. Avoiding the tombstone effect is not the only reason to create thermal reliefs—since the solder mask opening has the same dimension for both pads, it’s clear that one of the pads will appear bigger than the other.

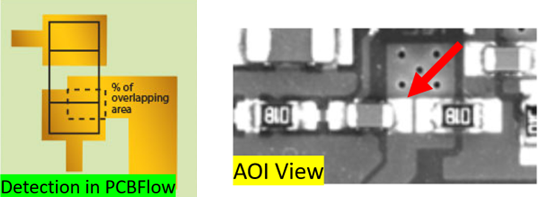

The solder volume depends on the stencil opening, but the height of the solder joint is influenced by its surface. The difference in height between solder joints will be detected by AOI/AXI and evaluated as a mistake. Even if this is accepted by IPC standards, the First-pass yield will be affected, and reaction is requested immediately. The process owner will decide to create a “special” shape in the AOI library with another properties. The standard component in the layout software library will create a non-standard AOI shape library.

However, if we can automatically check the solder mask design before the layout release, the SMT process will be improved. The PCBFlow constrain named “SMD Pad covered by Surface – Percentage Area” can detect and highlight the similar issues in the layout. During the check, PCBFlow will identify all the potential design mistakes and inform the user about the needed layout correction.

4. Simple Considerations when Designing PCB Prototypes for Sustainability

Printed Circuit Boards (PCBs) are the backbone of modern electronics, but the manufacturing process can have significant environmental impacts. To reduce the environmental footprint of electronics, it is important to design PCB prototypes with sustainability in mind. In this article, we will discuss several key considerations for designing sustainable PCB prototypes.

- Material Selection: The materials used in PCB production can have a major impact on the environment. By selecting environmentally friendly materials, such as lead-free solders, recycled materials, and biodegradable plastics, you can reduce the environmental impact of your PCB prototype.

- Efficient Design: An efficient design can reduce the number of materials and energy required to manufacture your PCB prototype. Consider using smaller components, reducing the number of layers, and optimizing the layout to reduce the environmental impact of your design.

- End-of-Life Considerations: The end-of-life of a PCB prototype should also be considered when designing for sustainability. Designing for easy disassembly and recyclability can reduce the waste generated when the product reaches the end of its life.

- Minimizing Waste: Minimizing waste during the production process can significantly reduce the environmental impact of your PCB prototype. By using efficient manufacturing processes and proper waste management, you can reduce the amount of waste generated during production.

In conclusion, designing PCB prototypes for sustainability requires careful consideration of materials, design, end-of-life, and waste. By incorporating these considerations into your design process, you can significantly reduce the environmental impact of your PCB prototype and contribute to a more sustainable future for electronics.

5. PCBflow Video Walkthroughs

- Creating & Managing Projects

- Running a Fabrication Analysis

- Different File Formats? No Problem

- Running an Assembly Analysis

- Interactive Board Viewer – Viewing the Results of DFM Analysis

- Get accurate price estimates, immediately

- Sharing a Project with our Support Team

- Networking & Collaborating

- PCB Manufacturers – Important Info

Creating & Managing Projects

PCBflow offers a simple and intuitive way to manage your projects and collaborate with your team. To manage your projects in PCBflow, simply create a new project and upload your design files and BOM. You can then use the project dashboard to track your progress, review DFM analysis results, and manage your team’s tasks and responsibilities.

You can also use the “Activity” tab to keep track of project updates and changes, and the “Notifications” feature to stay informed about important project events.

Running a Fabrication Analysis

To help you get started, we have created a short video tutorial that walks you through the process of running a fabrication analysis on PCBflow.

Here are the steps covered in the video:

- Log in to your PCBflow account and create a new project.

- Upload your PCB design files to the project.

- Click on the “Fabrication” tab in the top navigation bar.

- Choose the fabrication options that apply to your design.

- Click on the “Run Analysis” button to start the analysis process.

- Review the report and make any necessary changes to your design.

- Run the analysis again to ensure that any issues have been resolved.

With these simple steps, you can ensure that your PCB design is manufacturable and meets your specifications.

Different File Formats? No Problem.

Use DFM rules created by your preferred supplier, and easily upload your designs in ODB++, IPC2581, Gerber274x and many other common CAD formats.

Here are some tips to help you get started:

- Upload your Gerber files and Bill of Materials (BOM) to a new PCBflow project.

- Choose the correct PCB stack-up and set the manufacturing constraints that are specific to your design.

- Run a Design for Manufacturability (DFM) analysis to check for any potential issues with your design.

- Review the DFM report and make any necessary changes to your design or BOM.

- Run the analysis again to ensure that any issues have been resolved.

Running an Assembly Analysis

Assembly included PCBflow merges accurate part geometry to your design (provided by Valor Parts Library), and tests for assembly problems so you can adjust your board before it’s too late.

Here are the steps covered in the tutorial:

- Log in to your PCBflow account and create a new project.

- Upload your PCB design files and Bill of Materials (BOM) to the project.

- Click on the “Assembly” tab in the top navigation bar.

- Choose the assembly options that apply to your design, such as pick and place machine accuracy, solder paste stencil thickness, and component placement tolerances.

- Click on the “Run Analysis” button to start the analysis process.

- Review the report and make any necessary changes to your design or BOM.

- Run the analysis again to ensure that any issues have been resolved.

Interactive Board Viewer – Viewing the Results of DFM Analysis

DFM analysis is an essential step in ensuring the manufacturability and reliability of your PCB design. PCBflow offers a powerful DFM analysis tool that can help you identify potential issues and optimize your design for manufacturing.

- Smart, self-explanatory, and interactive – DFM report includes filtering, statistics, summary tables and error grouping.

- Easy zooming and navigation through all board layers, as well as interactive viewing of DFM results, powered by Valor Parts Library.

Get accurate price estimates, immediately.

PCBflow instantly shows updated cost and availability information for the components in a Bill of Materials (BOM), using the BOM Pricing and Sourcing tool. PCB designers can use the QuickPrice function (powered by our partner Boardera) to receive instant, accurate price estimates within PCBflow for the manufacturing and assembly of their projects. Manufacturers can easily become qualified QuickPrice providers in PCBflow, and receive notification each time a price estimate is requested.

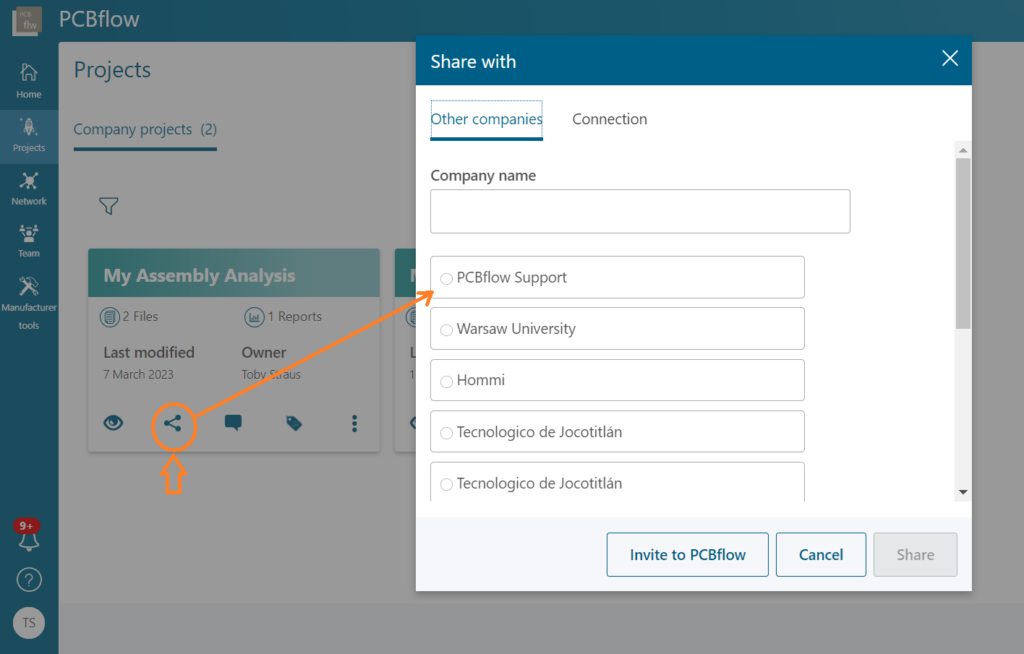

Sharing a Project with our Support Team

If you are experiencing any issues or need assistance with your PCB design process, the PCBflow support team is here to help. One way to get help is by sharing your project with our support team, so that we can review it and provide recommendations.

To share a project with our support team, simply follow these steps:

- Open the project that you want to share and click on the “Share” button in the top right corner of the screen.

- In the “Share Project” dialog box, enter “support@pcbflow.com” in the email address field.

- Click on the “Send Invite” button to send the invitation to our support team.

- Once our support team receives the invitation, we will be able to access your project and provide the assistance that you need.

By sharing your project with our support team, you can get the help you need to optimize your PCB design process and ensure the success of your projects.

Networking & Collaborating

Connect with your manufacturer to perform DFM based on their manufacturing capabilities and obtain feedback on design flaws early. Share ODB++ design files created by PCBflow to eliminate manufacture errors and shorten time to market. Your data is stored securely and only you decide who can share it.

- Converse with your manufacturer about your analysis results, specific to their DFM profile.

- Create and store unlimited projects.

- Review your DFM results any time from any location.

PCB Manufacturers – Important Info

Taking a few minutes to update your company profile can create a strong online presence, positively impact your business, and help your company stand out among the many PCB fab and assembly options available today.

Podcast - Sustainability Through Cloud Applications

Are cloud applications and sustainability just a pie in the sky vision? Not if you talk to Susan Kayesar, PCBflow product manager at Siemens. Susan maps the sustainability landscape, as she sees it, pointing out the potentially negative effects that “greenwashing” can have. She then takes us on a tour through DFM and industry standards development for sustainability, as well as some key new best practices that emerge from using a cloud-based platform model for business operations software systems.

You may also be interested in...

$video_id:WLvZM99PQ0g

What Is It? Why Does it Matter? - Lifecycle Insights

February 1, 2023What is Siemens PCBflow offering and why does it matter?

$video_id:qEiFcHEg-sY

$video_id:ZkdCOB5bMsY

$video_id:ZkdCOB5bMsY

Webinar: The State of DFM

September 1, 2022PCBflow significantly reduces the time and effort spent leading up to manufacture of prototypes and NPIs