Approval required to join the network.

Starting April 4, 2023, all companies are subjected to an approval process to be visible in the PCBflow network. To join the network, provide the required information in your Company Profile and submit your request.

The approval process is fast, but in some cases may take up to a few days. You will receive notification when your request is approved or if there are additional details required.

As part of this change, some PCBflow accounts were pre-approved to ensure continuity of service. If your company was pre-approved without completing all required information, please open your Company Profile and complete the missing information now.

DFM profile selection made easy

Its important to select the right DFM profile when you run DFM analysis. Now you can easily see all the manufacturers that are offering their DFM profile for you to use.

Use these 3 easy steps:

- Run your DFM.

- Choose your DFM partner.

- Select the right profile.

Of course, you can still choose a generic DFM profile provided by Siemens.

Download DFM results in Excel format

You can now download your DFM results to Excel format for offline review.

In the online viewer, choose between PDF and Excel format.

Click to contact your DFM partner

Its now easier than ever to contact your DFM partner – the people who set up your DFM rules.

- Contact information now appears at the top of the online report viewer, and on the project report tile.

- Click to automatically start an e-mail to the right people.

Reminder: make sure your company contact information is up-to-date so that its just as easy to find you!

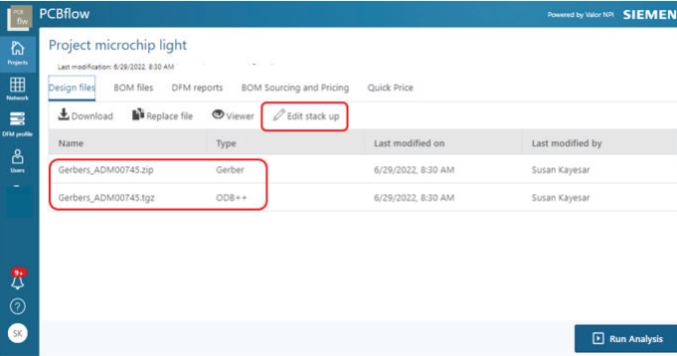

Auto-create dielectric layers for Gerber data

Gerber data lacks dielectric layers, so we added a button to auto-create a single dielectric layer between all inner layers.

You’ll find the button in our stackup editor. Make sure to set the correct thickness for the dielectric layers that are added (default .001 mil).

Upload accessory project files

Upload and store up to 10 additional files with each project, in the Files tab.

Use these files to easily pass additional information to your manufacturing partner, such as fab drawings, project specifications, readme files and more.

Accepted formats: .pdf, .doc,.xls, .png, .jpg, .txt, .dxf, .dwg

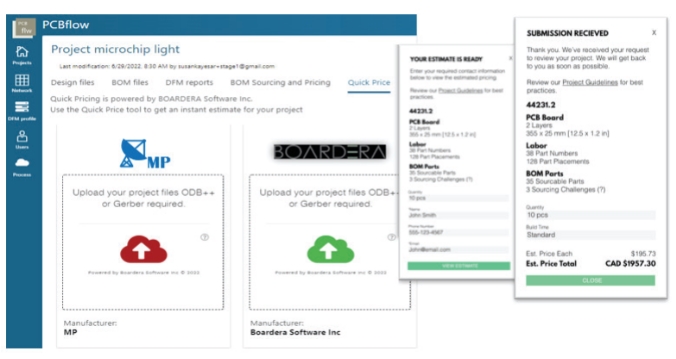

Easier BOM Pricing and Sourcing

Get instant, accurate component pricing and availability information with the BOM Pricing and Sourcing tool. The new interface makes it easier to understand the important information that this tool provides. Upload your BOM file in Excel format. Change selection of preferred suppliers at any time, and the results will be updated automatically.

Spare parts marked in BOM Pricing and Sourcing.

If you decide to buy more parts than you need in order to get a better price, we provide a handy calculation of how many spare parts you will be left with.

New company tags: “DFM Provider” and “QuickPrice”

Companies can earn tags for providing an original DFM profile and for becoming a QuickPrice provider.

The tags “DFM profile” and “QuickPrice” appear on the company card and can be used to search for a manufacturer in the network.

Manufacturers – now is a good time set up your DFM profile from Manufacturer Tools, and add your QuickPrice URL to your company profile.

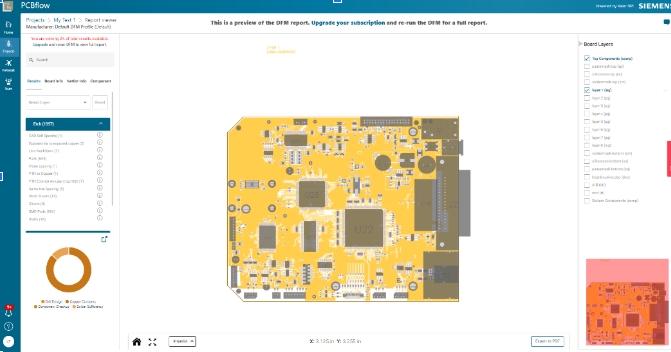

DFM Checks explained

We provide a searchable, comprehensive list of DFM checks that are available in PCBflow.

Note – not all DFM profiles are set to contain all checks but now it is easy to see which checks could be part of your DFM analysis.

Improved analysis progress bar

We value your time! The analysis progress bar has been improved to give a more accurate indication of how much work has already been completed and how much is left.

Remember, you can continue to work in PCBflow while your DFM analysis runs. We’ll notify you when its finished.